LONG-CUT DRY PASTA

PRODUCTION LINE

Various Types of Long-Cut Dry Pasta Production Lines

SUMMARY

Simple automation system equipped pasta production line main purpose is provide high quality product with low investment price. Using latest and newest technology, we can build-up or redesign your facility's manufacture ability to reach high quality product.

Our full automatic and semi automatic long-cut pasta production lines produced for whole day and various type of production capacity in an hour like 100 kg/h, 200 kg/h,300 kg/h, 500 kg/h, 1000 kg/h, 2000 kg/h, 3000 kg/h.

■The machine composition is entirely made of 304 high quality stainless steel.

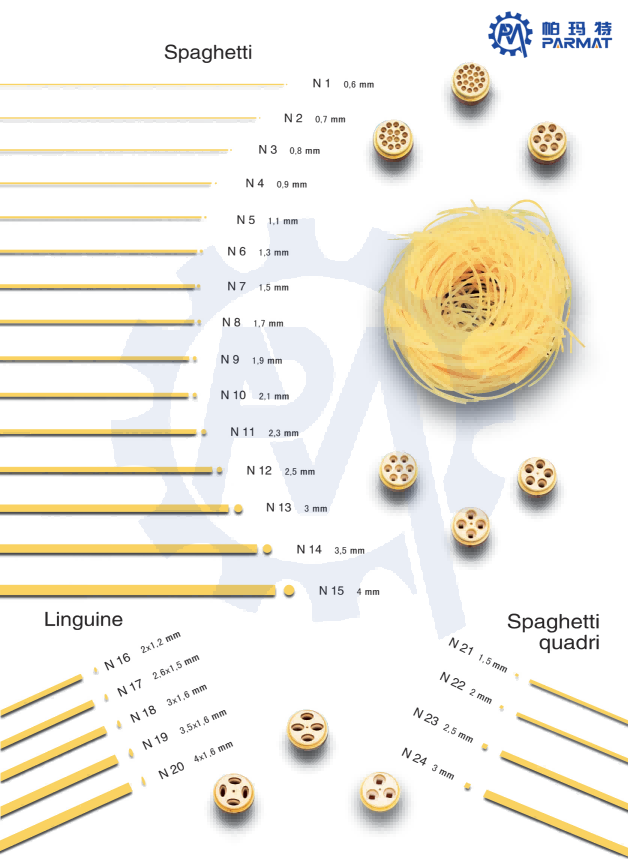

■Simple replacement of vacuum extrusion dies.

■Controllable mixer speed, vacuum extruder speed, spaghetti rod length.

■The wheat flour enters the spaghetti vacuum extruder for vacuum mixing, vacuum mixing, and vacuum extrusion.

■Vacuum extrusion standard ≥ 0.08MPA, high-quality extrusion of long-cut pasta without air and impurities.

■Waste recycling device, through pneumatic conveying pipeline to vacuum mixing tank.

■Automatic hanging bar device evenly cuts long spaghetti into sections.

■Sharp shears cut long-cut spaghetti equally neatly.

■Excess waste is conveyed to the recycling system via a conveyor belt.

■The height of all machine feet can be adjusted on the production line.

■Manual carts deliver long-cut pasta, greatly saving machine costs.

■Static or Continuous Dryer: Decomposition product moisture percentage. The drying process can be carried out at high or low temperature, and the temperature and humidity are automatically controlled.

■Temperature management during drying is important to avoid pasta breakage during packaging at the eating stage.

■The dryer can be static, by manually loading the trays into the insulated chamber, or continue to use a belt system to continuously load the trays into the drying process.

■Automatic quantitative packaging machine, easy to put spaghetti to complete the packaging.

■Low-cost input into production can eliminate automatic packaging machines and expensive equipment costs.

| MODEL TYPE | Explain |

|---|---|

| CQ100 100 kg/h |

Low-cost investment to replace continuous automatic drying systems with static dryers, including manual packaging instead of automatic packaging machines |

| CQ150 150 kg/h | |

| CQ200 200 kg/h | |

| CQ300 300 kg/h | |

| CQ400 400kg/h | |

| CQ600 600 kg/h |

Machines are highly automated using programmable logic controllers. They are called "production lines" because they contain a series of processing machines through which the dough passes. Dry pasta lines typically run continuously for up to six weeks and pack in shifts |

| CQ800 800 kg/h | |

| CQ1000 1000 kg/h | |

| CQ1500 1500kg/h | |

| CQ3000 3000kg/h |

-

■Stir to mix

This part is the beginning part of the journey pasta production. The raw materials are sent here first and the water mixes the flour according to the right ratio to provide the first mix - ■prepare the dough

After the ingredients section, the uniformly mixed ingredients are sent to the dough container, which is the first device on the line to produce dough. The prepared mixture is sent to the vacuum extruder with a special conveyor. The vacuum extruder is produced by specially designed PARMAT technology. After this part, the mixture reaches a vacuum container that sucks up the semolina flour and air bubbles in the water via a vacuum pump to give a smooth surface and a true yellow color on the pasta. Prepare the final state of the dough

-

■vacuum extrusion

-

The prepared dough is conveyed through a screw after vacuum stirring and vacuum extrusion, and enters the mold to extrude many spaghetti with the same thickness.

■Filament delivery

-

The spaghetti is conveyed and unfolded by wooden sticks, and there is a fan below to dry the surface moisture and separate the noodles.

■Automatic hanging rod

The spaghetti is transported to the hanger in an orderly manner.

-

■SHAPING PASTA

The long-cut pasta will be continuously cut into the same length, and then automatically arranged on the hanging rod waiting for the trolley to enter the drying room, and the cut waste will be recycled. - ■Dry pasta production line

- Our experience allows us to manufacture plants and complete production lines, dedicated to the widest range of corporate environments, with outputs ranging from 100 kg to 3000 kg per hour, thanks to continuous Fully automatic extruder combined with low temperature, static drying or continuous drying systems. Independent of the production output, an efficient extruder is essential for every plant and line to ensure the highest quality, with customized dosage, mixing and production according to the raw materials used and the type of product obtained.

Contact us to get offer and more information about our long-cut pasta production lines.

Tell us about your requirements for long-cut pasta production lines.

Kazakhstan office: 005063 Kazakhstan , Almaty, Utegen Batyra 17/3 office 9 , LLP “Dastan55” , +77089152800

Pakistan office: Company name: Century PremiumAddress:12 KM Satiana Road, AWANWALA Stop Ne Model City Faisalabad, PUNJAB, PAKISTANContact number: +92333 3311044Email: omer engg@hotmail.comceo@centurypremium.com

Indian office: New lmperial Associates Exim Pvt Ltd.Ground Floor,A-43, Sector 57, Noida (UP)-201301Phone :+91-120-4222032/4256354Mobile:+91-9315730010Email :iaplind@gmail.com