INDUSTRIAL AUTOMATION LONG-CUT DRY PASTA PRODUCTION LINE

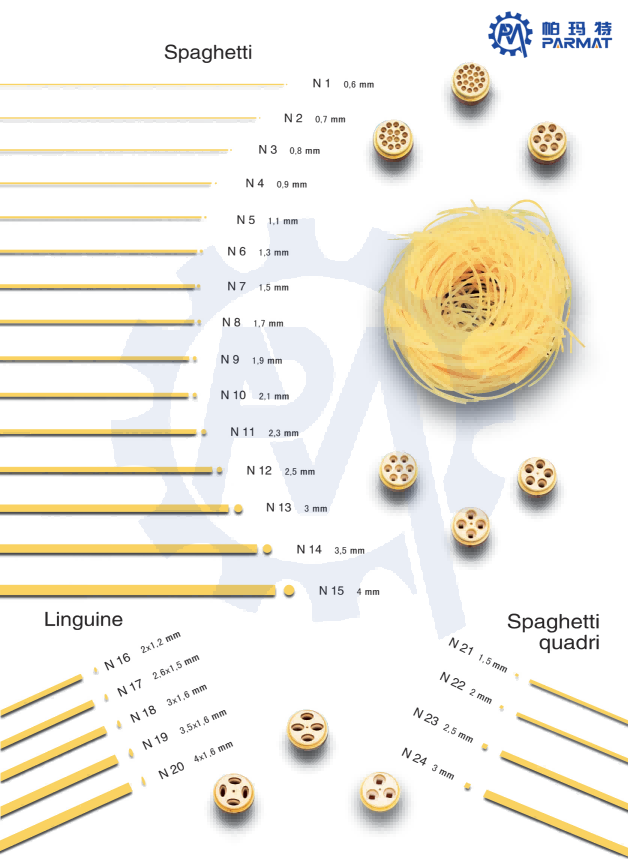

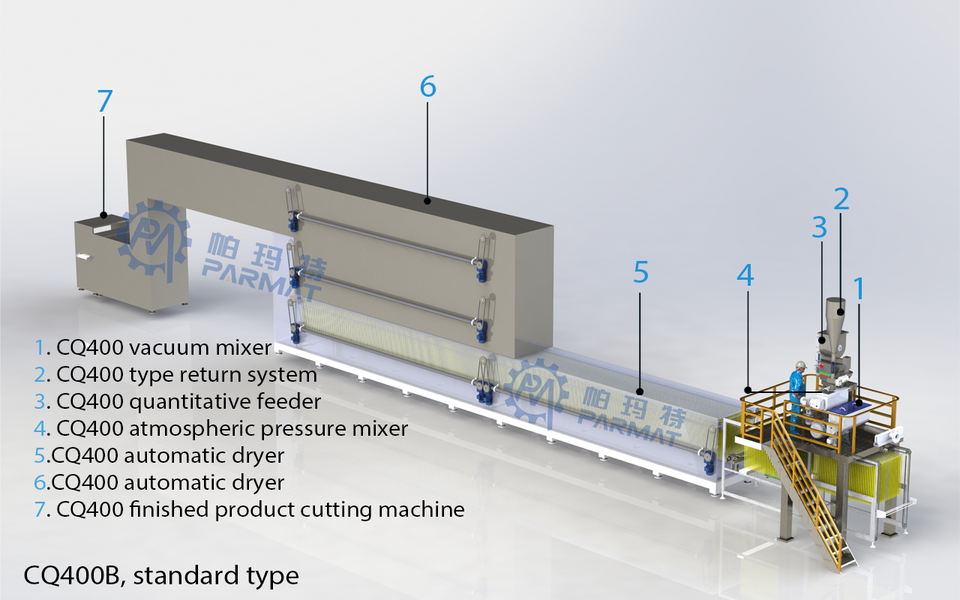

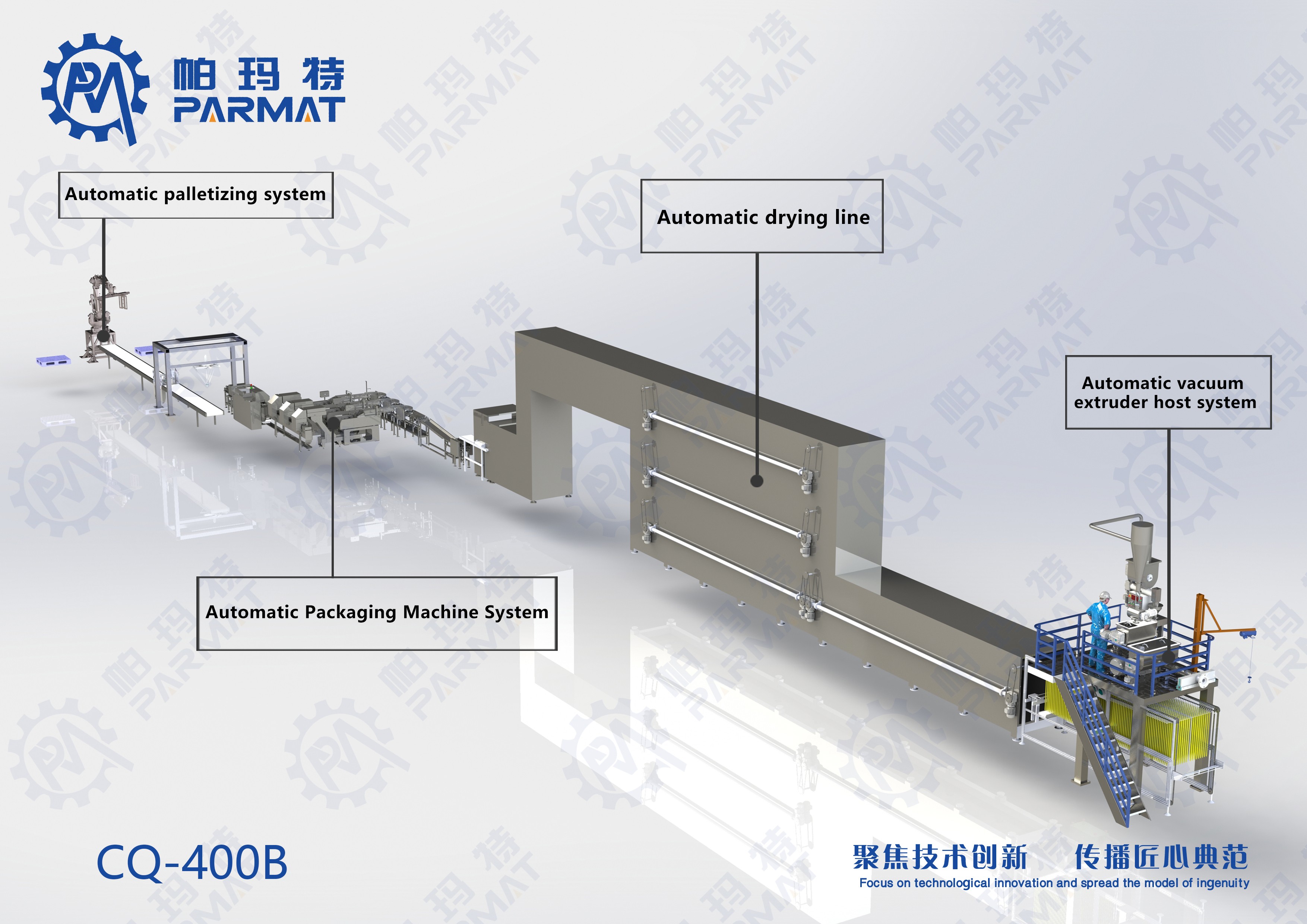

The whole process to make Long-cut pasta: The production line has a reasonable design and is produced by a fully automated assembly line, reaching the international advanced level. The host powder and water are accurately calculated and input into vacuum mixing, vacuum extrusion technology, and the drying system adopts constant temperature and humidity technology to realize full automatic control, which improves the manufacturing speed, increases the output, reduces labor costs, and improves product quality. The production process flow is: raw and auxiliary materials → first kneading → second vacuum kneading → vacuum extrusion → forming → pre-drying → main drying → cooling and cutting → measuring and packaging → product. It consists of feeding system, vacuum mixing system, vacuum extrusion molding system, constant temperature and humidity drying system, and automatic intelligent control system. To ensure the stability of the production process, the products have various shapes, smooth and beautiful appearance, good straightness and delicate texture.

Complex automation system equipped pasta production line main purpose is provide high quality product with low investment price. Using latest and newest technology, we can build-up or redesign your facility's manufacture ability to reach high quality product.

Our full automatic and semi automatic long-cut pasta production lines produced for whole day and various type of production capacity in an hour like 100 kg/h, 200 kg/h,300 kg/h, 500 kg/h, 1000 kg/h, 2000 kg/h, 3000 kg/h.